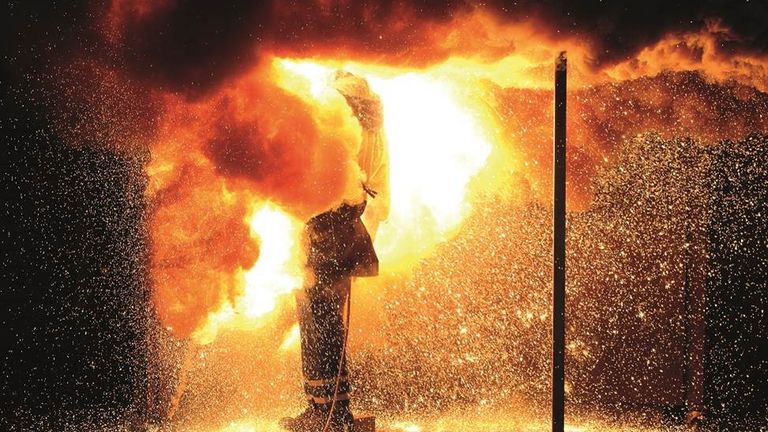

When oxygen (air), fuel, and heat (ignition/ energy) co-exist in any working environment, the probability of fire will always be greater than zero. Given this risk, prevention and control must be top of mind.

Are you choosing the best available, last line of defense with your protective clothing?

Beyond standard protection: What should be considered to maximize protection from fire risks?

The first step in properly evaluating flame resistant protective clothing is to ensure that it meets the minimum requirements as listed in NFPA 2112 and ISO 11612. However, it is important to assess other key performance factors in various exposure scenarios.

Aging of protective clothing

Two most common aging scenarios for protective clothing are:

- washing and cleaning

- working outdoors in the presence of sunlight

After-glow performance

After-glow performance on bottom edge ignition (ASTM D6413) after the source is extinguished to avoid heat transfer to the wearer.

Predicted body burns

The predicted body burns are defined according to the method selected ISO 13506 or NFPA 2112.

PROBAN® flame resistant fabric is engineered to exceed the basic requirements of NFPA 2112 and ISO 11612 and exhibits no after-glow on bottom edge ignition, the lowest predicted burns as per ASTM F-1506, and no change in flame resistant properties after exposure to sunlight.